Blog

Energy-Efficient Compressed Air Systems Can Contribute to Lower Operating Costs for Maine Manufacturers

This is the third blog in a series that highlights the benefits of Efficiency Maine’s Commercial and Industrial Custom Program incentives. To read the first blog, click here. To read the second blog, click here.

To some extent, compressed air is used in virtually all manufacturing facilities to power pneumatic equipment, handle materials, and accomplish a variety of process-specific tasks. It is a flexible energy source and a crucial utility in many processes.

Compressed air also is very energy-intensive and expensive to produce. For example, a 200-horsepower compressor operating 6,800 hours a year could cost $150,000 annually to operate at $0.15 per kilowatt-hour.1

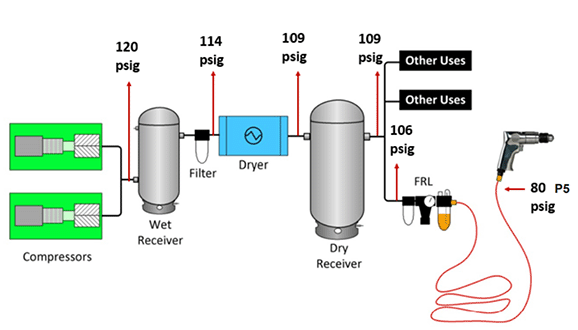

The components of compressed air systems typically include a reciprocating, rotary or screw compressor, a dryer to remove moisture, and one or more storage tanks to provide a buffer from compressed air end uses. The figure below from the Compressed Air and Gas Institute’s Compressed Air System Design manual shows a simplified system schematic and typical pressure drops across the supply-side components.

As energy intensive systems, there are many opportunities for energy efficiency and generally high returns on investments.

For instance, rotary screw compressors with Variable Frequency Drives are generally considered the most efficient air compressors. When paired with cycling refrigerated dryers and plenty of storage, they create a robust and high-efficiency system design that is usually eligible for Efficiency Maine incentives. Other opportunities to reduce compressed air system operating costs include eliminating leaks and sources of wasted compressed air, increasing the size of piping to allow for reduced operating pressures, and installing no-loss condensate drains.

High-efficiency compressors smaller than 90 horsepower are eligible for Efficiency Maine Prescriptive Program incentives as long as you work with a Qualified Partner. Compressed air systems larger than 90 horsepower are eligible for Efficiency Maine Custom Program incentives. Systems larger than 90 horsepower are also eligible for a 50% cost share from the Custom Program for compressed air leak surveys and repairs.

A sudden system failure can lead to hasty replacements, often using low-cost and low efficiency in-stock equipment. To avoid this potential fire drill, consider speaking with your preferred vendor about high-efficiency replacement options for older equipment before an unexpected failure leads to production interruptions, and rushed purchase decisions.

To learn more about Efficiency Maine’s Commercial and Industrial Custom Program click here.

To subscribe to Efficiency Maine’s blog and receive the latest program updates, click here.